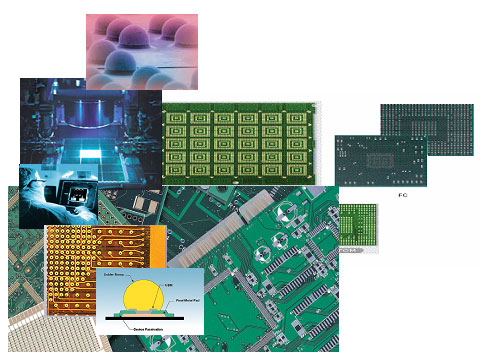

Pattern generators are considered to be complex tools in manufacturing of semiconductor devices. High requirements to such equipment can be met only with the help of high-end technology.

KBTEM-OMO has extensive experience in the development of opto-mechanical equipment. The model line of multichannel laser pattern generators for microelectronics built on the raster scan concept is characterized by exceptional functional features:

- direct writing on wafers (maskless optical lithography);

- overlay option;

- high throughput;

- process switch to mask writting mode.

The universality of such high-performance equipment makes it indispensable for scientific institutions and microelectronics manufacturers.

EM-5389 Multichannel laser pattern generator